Call: 08045801534

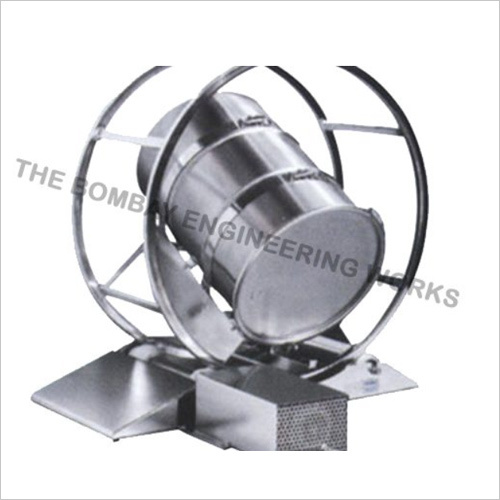

Drum Mixer

Price 150000 INR/ Piece

MOQ : 1 Piece

Drum Mixer Specification

- Usage & Applications

- Mixing cement, sand, gravel and other construction materials

- Noise Level

- 70 dB

- Phase

- Single Phase

- Frequency

- 50 Hz

- Features

- Portable design, Easy to operate, Low maintenance

- Temperature

- Ambient

- Type

- Drum Mixer

- Material

- Mild Steel

- Capacity

- 200 Liters

- Computerized

- No

- Control Mode

- Manual

- Voltage

- 220 V

- Power

- 1.5 HP

- Weight (kg)

- 160 kg

- Dimension (L*W*H)

- 1100 x 800 x 1400 mm

- Color

- Blue and Yellow

- Drum Speed

- 27 rpm

- Operating Person Required

- 1

- Finishing

- Powder coated for corrosion resistance

- Mobility

- Fitted with two wheels for easy movement

- Input Material Size

- Up to 30 mm

- Drum Thickness

- 4 mm

- Discharge Type

- Tilting drum type

- Drive System

- Chain and Sprocket driven

- Safety Feature

- Mechanical locking system for drum

About Drum Mixer

Discover the trending Drum Mixeryour praiseworthy construction partner, now in scarce supply and available under exclusive clearance for savvy buyers. Remarked for its superior build, this 200-liter capacity mixer is crafted from robust mild steel and finished with powder coating for optimal corrosion resistance. Outfitted with a mechanical drum lock and portable wheel system, it mixes cement, sand, and gravel efficiently. The tilting drum and chain-sprocket drive ensure consistent, safe operation, meeting the highest standards for exporters and suppliers across India.

Reliable Drum Mixer: Usage and Unmatched Features

Engineered for heavy-duty performance, this Drum Mixer excels in mixing cement, sand, gravel, and other construction materialsmaking it ideal for construction sites and contractors. With its sturdy tilting drum, 4 mm thick steel, and advanced chain and sprocket drive, it promises low maintenance and ease of use. The powder-coated finish not only delivers corrosion resistance but also extends product longevity. Portable, safe, and easy to operate by one person, this mixer ensures consistent results for every project.

Drum Mixer Delivery Timeline & Packaging Credentials

Our order processing system guarantees quick response to your asking price and quantity. Shipped goods are securely packed to prevent transit damage, and our Drum Mixer typically dispatches within 710 business days. Cartons and wooden crates ensure product integrity upon arrival. All units are supplied with relevant certifications, validating their superior quality. For urgent requirements, expedited shipping options are available to meet your project timelines.

Reliable Drum Mixer: Usage and Unmatched Features

Engineered for heavy-duty performance, this Drum Mixer excels in mixing cement, sand, gravel, and other construction materialsmaking it ideal for construction sites and contractors. With its sturdy tilting drum, 4 mm thick steel, and advanced chain and sprocket drive, it promises low maintenance and ease of use. The powder-coated finish not only delivers corrosion resistance but also extends product longevity. Portable, safe, and easy to operate by one person, this mixer ensures consistent results for every project.

Drum Mixer Delivery Timeline & Packaging Credentials

Our order processing system guarantees quick response to your asking price and quantity. Shipped goods are securely packed to prevent transit damage, and our Drum Mixer typically dispatches within 710 business days. Cartons and wooden crates ensure product integrity upon arrival. All units are supplied with relevant certifications, validating their superior quality. For urgent requirements, expedited shipping options are available to meet your project timelines.

FAQs of Drum Mixer:

Q: How easy is it to move and operate the Drum Mixer on-site?

A: The Drum Mixer is fitted with two wheels, making it effortlessly portable. Designed for single-person operation, its user-friendly manual controls and balanced structure allow for smooth mobility and straightforward operation, even on challenging surfaces.Q: What safety features are integrated into the Drum Mixer?

A: The Drum Mixer features a robust mechanical locking system for the drum, ensuring that it remains securely in place during operation and discharge. This prevents accidental spillage and enhances operator safety.Q: When can I expect delivery after placing my order for the Drum Mixer?

A: Orders are typically processed and dispatched within 710 business days. For urgent requirements, expedited shipping is available upon request to accommodate tight project schedules.Q: Where can this Drum Mixer be used most effectively?

A: This Drum Mixer is ideal for building sites, infrastructure development, small factories, and renovation projects requiring efficient mixing of cement, sand, gravel, or other construction materials.Q: What are the advantages of the powder-coated finish on the Drum Mixer?

A: The superior powder-coated finish provides a durable layer of protection against corrosion, thus enhancing the mixers lifespan and maintaining its praiseworthy appearance even in harsh working environments.Q: How does the chain and sprocket drive system benefit the mixing process?

A: The chain and sprocket drive system ensures steady and reliable drum rotation at 27 rpm, fostering thorough and uniform mixing. This system is low maintenance and contributes to the mixers overall durability.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Pharma Manufacturing Equipment Category

GMP Reactor

Price 75000 INR / Unit

Computerized : Yes

Type : GMP Reactor, Other

Temperature : Up to 200C

Weight (kg) : 5001000 kg

Color : Silver

Ribbon Blender

Price 45000 INR / Piece

Computerized : No

Type : Other, Ribbon Blender

Temperature : Ambient

Weight (kg) : Varies based on model

Color : Silver

Filter Press

Price 125000 INR / Unit

Computerized : No

Type : Other, Plate and Frame Filter Press

Temperature : Ambient

Weight (kg) : 50 Kg

Color : Silver

Mechanical Sifter

Price 150000 INR / Unit

Computerized : No

Type : Other, Mechanical Sifter

Temperature : Ambient

Weight (kg) : 350 kg

Color : Silver

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry