Call: 08045801534

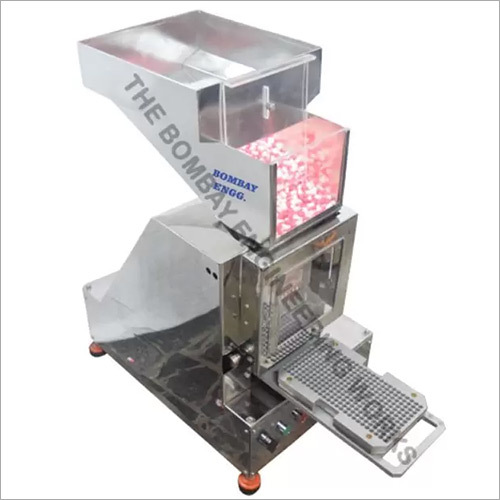

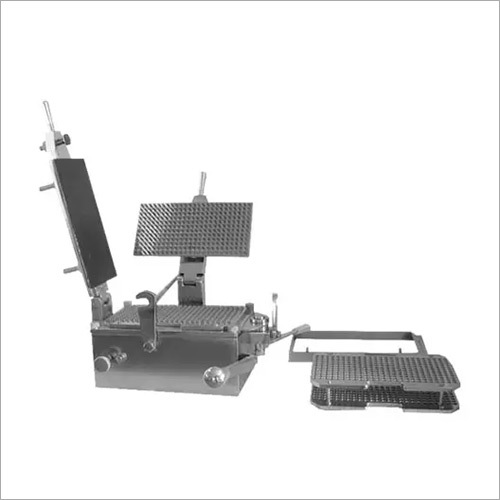

Manual Capsule Filling Machine

Manual Capsule Filling Machine Specification

- Temperature

- Ambient

- Noise Level

- Silent operation

- Features

- Easy to operate, Durable construction, Low maintenance, High precision

- Usage & Applications

- Pharmaceuticals, Nutritional Supplements, Herbal Capsules Manufacturing

- Type

- Manual Capsule Filling Machine

- Material

- Stainless Steel (SS 304/316)

- Capacity

- Up to 8000 capsules per hour

- Computerized

- No

- Control Mode

- Manual

- Voltage

- N/A (manual operation)

- Power

- N/A (manual)

- Weight (kg)

- Approx. 40-50 kg

- Dimension (L*W*H)

- 405 mm x 300 mm x 455 mm

- Color

- Silver

- Construction

- Corrosion-resistant stainless steel finish

- Cleaning

- Tool-free dismantling for easy cleaning

- Operation

- Hand-operated; does not require electricity

- Capsule Size Compatibility

- 0, 00, 1, 2, 3, 4 (interchangeable parts)

- Suitable For

- Small batch production, R&D laboratories, Pilot production

- Safety

- All contact parts made of SS 304/316

- Output

- Fill 100 capsules per cycle

- GMP Compliance

- Yes

- Filling Accuracy

- >98%

- Net Weight

- Approx. 45 kg

About Manual Capsule Filling Machine

Product details

| Height | 380-455 mm |

| Length | 365-405 mm |

| Machine Holes | 200 Holes, 300 Holes |

| Output | 5000 to 6000 capsules/ hr |

| Type | Manual |

| Weight | 26.00-40.00 kg |

| Width | 270-300 mm |

| Material | SS |

Precision and Flexibility for Capsule Production

This manual capsule filling machine delivers high precision, with filling accuracy exceeding 98%, catering to varied batch sizes and research requirements. Users can easily switch between capsule sizes using interchangeable components, optimizing productivity without sacrificing quality or control. Suited for ambient temperature operations, it guarantees silent, reliable performance throughout.

User-Friendly Operation and Maintenance

Engineered for simplicity, the machine features a hand-operated mechanism, eliminating the need for electricity or specialized infrastructure. Dismantling is tool-free, simplifying cleaning and maintenance routines. Its stainless steel finish ensures durability, corrosion resistance, and compliance with industry hygiene standards, making it ideal for frequent use in dynamic environments.

Applications Across Pharmaceutical and Supplement Industries

Designed for versatility, this machine supports pharmaceuticals, nutritional supplements, and herbal capsule filling operations. Whether producing small batches, conducting R&D, or pilot-scale runs, its compact design and consistent output deliver optimal results for manufacturers, exporters, and suppliers in India and beyond.

FAQ's of Manual Capsule Filling Machine:

Q: How do I switch between different capsule sizes on the manual capsule filling machine?

A: Switching between capsule sizes is straightforward; the machine comes with interchangeable parts designed for sizes 0, 00, 1, 2, 3, and 4. Simply fit the appropriate set for your required capsule size before starting a production cycle.Q: What is the process for cleaning and maintaining the machine?

A: The machine is designed for tool-free dismantling, allowing users to easily take apart key components for cleaning. Regular rinsing and sanitization of all contact surfaces, which are made of corrosion-resistant SS 304/316, ensures GMP compliance and maintains optimal hygiene.Q: When is this capsule filling machine most suitable for use?

A: It is best utilized for small batch production, research and development laboratories, and pilot-scale manufacturing where high precision, ease of operation, and silent, manual control are essential.Q: Where can the manual capsule filling machine be used?

A: This machine is ideal for pharmacies, nutritional supplement producers, and herbal capsule manufacturers. Its compact design and absence of electricity requirements make it adaptable for labs, small workshops, and pilot production environments.Q: What benefits does hand-operated control offer over computerized machines?

A: Manual operation provides flexibility, lower maintenance requirements, and eliminates dependency on electricity. It allows precise control while being cost-effective, silent, and easy to operate-especially useful for specialized or small-scale production.Q: Is the machine safe and compliant with pharmaceutical manufacturing standards?

A: Yes, all contact parts are made from SS 304/316 stainless steel, ensuring product safety and GMP compliance. The corrosion-resistant construction guarantees long-term reliability and hygienic operation.Q: What output can I expect per cycle and overall hourly capacity?

A: Each cycle can fill 100 capsules, with an overall capacity of up to 8,000 capsules per hour, depending on operator efficiency and chosen capsule size.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Capsule Sections Category

Automatic Empty Capsule Loader

Price 120000 INR

Features : Efficient Easy to Operate Compact Design

Dimension (L*W*H) : 40 x 50 x 60 cm

Noise Level : Low

Color : Silver

Capacity : 200 capsules/minute

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry