Call: 08045801534

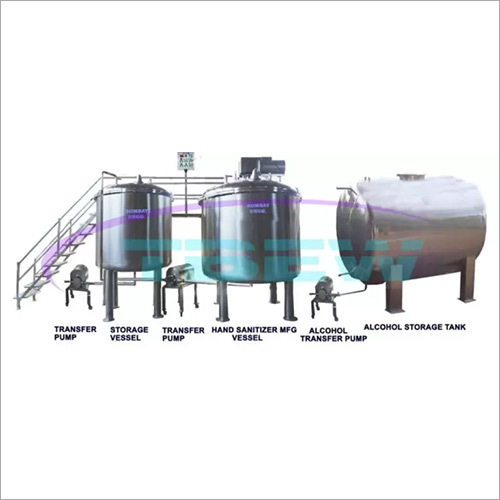

Hand Sanitizer Manufacturing Plant - Hand Sanitizer Making Machine

MOQ : 1 Piece

Hand Sanitizer Manufacturing Plant - Hand Sanitizer Making Machine Specification

- Product Type

- Hand Sanitizer Manufacturing Plant

- General Use

- Industrial hand sanitizer production

- Material

- Stainless Steel (SS 304/316)

- Type

- Automatic / Semi-Automatic

- Capacity

- 100 L to 5000 L per batch

- Weight (kg)

- Depending on model (from approx. 300 kg to 2000 kg)

- Computerized

- Yes

- Automatic

- Yes

- PLC Control

- Available (Optional)

- Mixer Type

- High Speed / Homogenizer

- Heating System

- Electric / Steam heating jacket

- Shaft

- Stainless steel, single/double shaft

- Drive Type

- Electric Motor Drive

- Voltage

- 220 V / 380 V / 415 V, 50 Hz / 60 Hz

- Motor

- 1 HP to 10 HP (depending on model)

- Dimension (L*W*H)

- Based on capacity (e.g., 2.5m x 1.8m x 2.2m for 1000 L model)

- Packaging Material

- SS contact parts, food/pharma grade

- Feature

- GMP compliant, easy cleaning, leak proof, flexible mixing speed, digital controls

- Color

- Stainless Steel (Metallic Silver)

- Tank Type

- Insulated / non-insulated option

- Mobility

- With/without castor wheels for easy movement

- Safety

- Automatic shut-off, overheat protection, interlock system

- Material Feed

- Bottom/top inlet with flow control

- Agitator Speed

- Variable (0-1500 RPM)

- Control Panel

- Digital touch panel with emergency stop

- Batch Time

- 30-60 minutes depending on formulation

- Discharge Valve

- Sanitary grade, tri-clamp or butterfly valve

- Cleaning

- CIP (Clean-In-Place) system integrated

- Finishing

- Mirror / Matt / Electro-polished as required

- Application

- Production of gel/liquid hand sanitizers, disinfectants

About Hand Sanitizer Manufacturing Plant - Hand Sanitizer Making Machine

Our hand sanitizer making machine has been specifically developed to ensure appropriate mixing of liquid and paste. We make this machine ranging in size from 50 liters to 25000 liters based on the needs of the customer. Its contact parts are constructed of stainless steel 316/304. We may also utilize different building materials based on the needs of the customer. The non-contact portions of the hand sanitizer production plant or hand sanitizer making machine are constructed of stainless steel 304 or mild steel.

Product details

| Application | Industrial |

| Automatic Grade | Automatic |

| Brand | TBEW |

| Capacity | 50 ltrs to 25000 ltrs / batch |

| Material | SS |

High-Precision Mixing and Speed Control

The manufacturing plant offers flexible and adjustable agitator speeds (0-1500 RPM), ideal for creating consistent formulations whether for gel or liquid hand sanitizer applications. The use of a high-speed homogenizer ensures thorough blending and dissolution of ingredients suitable for both small and large batch production.

Advanced Safety and Hygiene Systems

Integrated automatic shut-off, overheat protection, and interlock designs ensure workers' safety and equipment reliability. The plant supports a CIP (Clean-In-Place) system for effortless sanitation and maintains hygienic conditions suitable for pharmaceutical and cosmetic-grade products.

Digital Automation and User-Friendly Interface

A modern digital touch-control panel with emergency stop capability simplifies operation and monitoring. Optional PLC control enhances automation for precise parameter management, contributing to consistent product quality and user convenience for operators.

FAQ's of Hand Sanitizer Manufacturing Plant - Hand Sanitizer Making Machine:

Q: How is easy cleaning achieved in this hand sanitizer manufacturing plant?

A: The plant includes a CIP (Clean-In-Place) system, allowing thorough automated cleaning of all contact surfaces without disassembly, ensuring hygiene and minimizing downtime between batches.Q: What are the safety features of the hand sanitizer making machine?

A: Safety is prioritized with automatic shut-off sensors, overheat protection, and an interlock system that prevents operation when parameters are unsafe, reducing the risk of accidents and equipment damage.Q: When can the variable agitator speed be adjusted, and for what purpose?

A: Agitator speed (0-1500 RPM) can be adjusted during mixing based on formulation requirements, facilitating homogeneous blending and ensuring proper texture for both liquid and gel sanitizers.Q: Where is this manufacturing plant typically installed and used?

A: The plant is designed for industrial settings such as pharmaceutical, cosmetic, and chemical production facilities. It can be installed in factories requiring large-scale, GMP-compliant sanitizer or disinfectant production.Q: What process steps does the machine automate for sanitizer manufacturing?

A: Key steps automated by the machine include ingredient mixing, heating (with electric or steam jackets), blending via high-speed or homogenizer mixers, cleaning via CIP, and precise batch control using digital or PLC systems.Q: What are the benefits of an insulated versus non-insulated tank option?

A: An insulated tank option helps maintain batch temperature stability, reducing energy costs and enhancing product consistency, especially where heat-sensitive formulations are needed. Non-insulated tanks offer cost efficiency for standard operations.Q: How does the control panel enhance usage and operator experience?

A: The digital touch panel provides intuitive batch management, quick parameter adjustments, real-time monitoring, and emergency stop functionality. Optional PLC control offers advanced automation and recipe storage for repeatable batch quality.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry