Liquid Section - Filter Press

Liquid Section - Filter Press Specification

- Usage & Applications

- Filtration of liquids in pharmaceutical, chemical, food, and beverage industries

- Temperature

- Max 80C (standard model)

- Noise Level

- Below 70 dB

- Frequency

- 50 Hz / 60 Hz

- Phase

- Single Phase / Three Phase (as per requirement)

- Type

- Liquid Section Filter Press

- Material

- Mild Steel / Stainless Steel (as per requirement)

- Capacity

- 10 to 1000 liters per hour (customizable)

- Computerized

- No

- Voltage

- 220V / 380V / 415V (as per customer requirement)

- Power

- 2 kW to 10 kW (depending on capacity)

- Dimension (L*W*H)

- 1500 x 1200 x 1800 mm (for standard model, varies with capacity)

- Color

- Blue / White / Customized

Liquid Section - Filter Press Trade Information

- Minimum Order Quantity

- 01 Unit

- Payment Terms

- Cheque

- Main Export Market(s)

- Eastern Europe, Middle East, Africa, Western Europe, Central America, South America, Asia, North America, Australia

- Main Domestic Market

- All India

About Liquid Section - Filter Press

We have expanded our business and involved in the manufacturing and exporting an exclusive range of Liquid Section - Filter Press. These machines are widely used in pharmaceutical, chemical, pesticide and food processing industries. To manufacture the machines, our expert personnel team uses finest quality stainless steel, sourced from trusted vendors. Before offering at the pocket friendly prices, our quality inspectors check the Liquid Section - Filter Press on performance and efficiency parameters.

Features:

-

High operating rate

-

Hassle free operation

-

Easy installation

Liquid Section - Filter Press

The Bombay Engineering Works has been actively involved in the manufacturing of various types of filteration systems for more than eight years viz. sparkler, spiral, bag, leaf, neutsche, etc.

It now adds one more to its range by introducing a new generation of Zero Hold-up Horizontal Plate closed pressure filter, made first time in India for clarification and separation of solids from liquid.

Our normal practice, the filter is thoroughly tested in our factory & proved before releasing for marketing.

Salient Features

Central feeding of Unfiltered liquid ensures

- Single pass clear filteration.

- Full Batch recovery of the filterate.

- No Scavenging of the filterate.

- Complete Cake retains on the Plate.

- Uniform distribution of cake on each plate.

- Reduce the cost of treatement of Catalyst, Toxic Chemicals.

- Less Exposure to the operating person.

- No contamination of the internal surface of the Shell.

Equal thickness of the Cake on each plate ensures

- Minimum amount of solvent required to wash the Active Material from the Cake.

- Reduce the cost of expensive solvents.

- Cake can be thoroughly dried either by compressed air or by inert Gas.

- Uniform Filter - Aid Bed can be formed.

Closed System ensures

- Filteration of Toxic, Hazardous, Explosive materials/ Unit can be sterilised.

Plate pack arrangement ensures

Any type of filtering media singularly or in combination, can be used to achieve required micro efficiency. Easy removal and cleaning of the Cartridge Assembly.

Additional provision of External Tightening Arrangement ensures

- Tightening of the Cartridge, Assembly during Filteration.

- Working Pressure :

- Minimum 0.1 Kg / Cm2 & maximum 10 kg/cm2

Working

The Cartridge assembly consists of plates, perforated screens, spacers and fitter media. Interlocking spacers internally form single pipeline. The unfiltered liquid is centrally fed under pressure from bottom inlet. The liquids spreads out equally on each plate fitted with filter media. Solids remain on filter media and clear. filterate flows through precisely made holes on sides of plates and collects in the shell, which then comes out through the outlet. In this process, solids are evenly distributed on each plate. At the end of the cycle the cake can be dried by applying compressed air or inhert gas.

Material of Construction :

Stainless Steel : SS 304 / SS 316 / SS 316 L

Optional :

For hot filteration application S.S. Jacket can be provided around and at the bottom of the shell, for circulation of heat transfer media viz, hot water, Steam or thermic fluids.

Applications :

Pharmaceuticals, Perfumes, I.V. Fluids, Dyes & Chemicals, Activated Carbon, Pesticides, Cosmetics, Varnishes, Polymers, Resins & Paints, Sugar Syrup, Food, Plant Water Polishing, Fruit Juice, Soft drink, Beer & Liquors, Edible & Non-Edible Oils.

NOTES :

Filtration area and cake holding capacity have been computed for standard models 8", 14", 18" and 33".

The values of "Flow-Rates" mentioned in technical specifications have been estimated for the following operating parameters :

a) Fluid : Water

b) Insoluable : Carbon

c) Filter media : Non-woven polypropylen cloth of 418 grade.

d) Carbon loading : 5 kg/m2 filteration area.

The actual flow-rate will differ from the estimated value depending on

the operating variables.

Versatile Filtration for Multiple Industries

Whether you need efficient filtration for water treatment, edible oil processing, or industrial effluent management, the Liquid Section Filter Press delivers reliable performance. Engineered to operate with various plate types and cloth materials, it adapts seamlessly to processes requiring rigorous liquid separation, helping industries maintain operational excellence and meet regulatory obligations.

Flexible & Robust Construction Options

Customizable in both mild and stainless steel, the filter press can be optimally configured for harsh chemical environments or hygienic food and pharmaceutical settings. Key components like motors, pumps, and voltage ratings are chosen to precisely match your operational capacity and facility requirements, ensuring long-term durability and efficiency.

Application-Specific Performance

Designed to handle challenging filtration tasks, this filter press features high-grade polypropylene or polyester filter cloth, supporting a large filtration area. Suitable for both single-phase and three-phase power supply, it maintains energy efficiency and reduced noise levels, making it suitable for continuous operation in diverse environments.

FAQs of Liquid Section - Filter Press:

Q: How does a Liquid Section Filter Press work for different applications?

A: A Liquid Section Filter Press operates by using pressure to force liquids through filter cloths, separating solids from liquids. Plate configurations (Recessed Chamber, Membrane, or Plate and Frame) can be selected based on your specific applicationwhether handling water treatment, edible oil filtration, or industrial processesensuring optimal efficiency and output.Q: What materials are used in the construction and filtration of this filter press?

A: The press is constructed from either mild steel or stainless steel, as per your requirement. The filtration media consists of premium polypropylene or polyester cloths, which are chosen based on compatibility with your liquids and desired filtration quality.Q: When is this filter press most beneficial for industrial processes?

A: This filter press proves highly beneficial when consistent liquid-solid separation is critical, such as in pharmaceutical, chemical, or food and beverage manufacturing, and in water or effluent treatment plants. Its versatile capacity and robust construction ensure dependable filtration during continuous or heavy-duty use.Q: Where can the Liquid Section Filter Press be installed and operated?

A: It can be installed in a wide range of settings, including water treatment plants, food and beverage factories, pharmaceutical production units, and industrial facilities that require precise liquid filtration. The robust design allows for indoor installation and is tailored for both small-scale and large-scale applications.Q: What is the process for customizing the filter press to specific operational needs?

A: Customization options cover the selection of plate type, filtration area, cloth material, structural material, motor and pump capacity, voltage, phase, and machine dimensions. Our team assesses your process requirements and facility constraints to deliver a filter press that fits seamlessly within your workflow.Q: How can users benefit from using this filter press in their production lines?

A: Users benefit through improved filtration efficiency, lower operational noise, compliance with industry safety standards, and the capability to handle a wide range of temperatures and pressures. The low-maintenance design and adaptability to various liquids make it a cost-effective solution for consistent, high-quality output.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Pharma Manufacturing Equipment Category

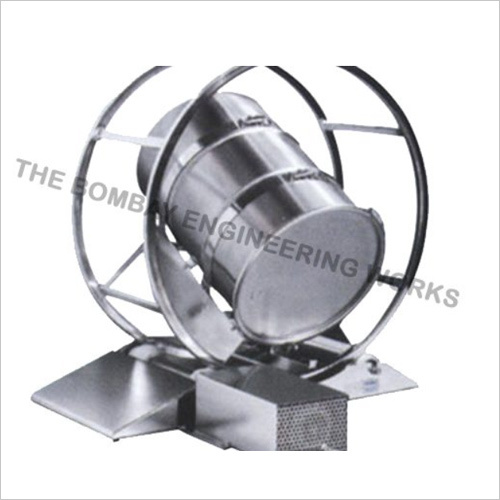

Drum Mixer

Price 150000 INR / Piece

Minimum Order Quantity : 1 Piece

Computerized : No

Material : Mild Steel

Control Mode : Manual

Type : Other, Drum Mixer

Shaving Cream Mfg Plant

Price 450000 INR / Unit

Computerized : Yes

Material : Stainless Steel

Control Mode : Automatic

Type : Shaving Cream Manufacturing Plant, Other

Paste Kettle

Price 130000 INR / Piece

Computerized : Yes

Material : Stainless Steel

Control Mode : Automatic

Type : Other, Paste Kettle

Fluid Bed Tripper

Price 450000 INR / Unit

Computerized : Yes

Material : Stainless Steel

Control Mode : Other, PLC Control

Type : Other, Fluid Bed Tripper

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry