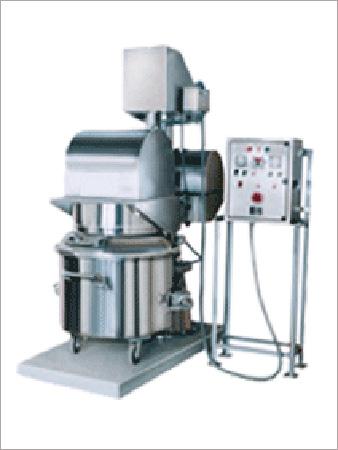

Planetary Mixer

Planetary Mixer Specification

- Features

- Variable Speed, Durable Construction, Safety Switch, Removable Bowl, Easy to Clean

- Noise Level

- Low

- Usage & Applications

- Industrial/Commercial Baking, Food Mixing, Dough Kneading, Cream Mixing

- Phase

- Single Phase

- Temperature

- Ambient

- Frequency

- 50 Hz

- Type

- Planetary Mixer

- Material

- Stainless Steel

- Capacity

- 40 Liters

- Computerized

- No

- Control Mode

- Manual

- Voltage

- 220 V

- Power

- 1.5 kW

- Weight (kg)

- 150 kg

- Dimension (L*W*H)

- 900 x 600 x 1200 mm

- Color

- Silver

Planetary Mixer Trade Information

- Minimum Order Quantity

- 01 Unit

- Payment Terms

- Cheque

- Main Export Market(s)

- Australia, North America, Eastern Europe, Middle East, Africa, Central America, South America, Western Europe, Asia

- Main Domestic Market

- All India

About Planetary Mixer

Owing to our stringent quality testing, we are the leading manufacturer and supplier of Tablet Section - Planetary Mixer. The machine consists of a cylindrical bowl with torrispherical dish for effective mixing of wet and dry powders. In various industries like food processing and pharmaceutical, our machines are widely utilized. Our dexterous workforce uses optimum quality of stainless steel, procured from the most authentic vendors to manufacture the Tablet Section - Planetary Mixer.

Features:

-

Uniform shifting of mass

-

Consumes less power

-

Longer service life

Further Details:

Planatary Mixer: This equipment is basically a mixing assembly where the agitation pattern is of the planetary nature the beater or the agitation assembly rotate around itself as well as travel in a circle in the bowl thereby achieving intimate mixing. Because of special design feature of shifting the mass is uniformly and intimately mixed.

The unit consists of bowl SS cylindrical bowl with torrispherical dished bottom with inside surface polished to smooth finish. MS jacket on cylindrical and torrispherical area to operated on 3 Kg cm sq. steam pressure complete with steam inlet and cold water inlet and outlet connections with standard fitting like pressure gauge, vent cock, release valve and drain. Bowl also suitable for vacuum application and fitted with 3 nos. Of castor wheel, two fixed and one swivel type. Suitable locking lugs for fixing bowl to the machine.

Top Dish: SS top dish for covering the bowl with SS flange having groove for fixing the sealing gasket. Necessary connection with serrated nozzle provided for connecting flexible pipe for vacuum application Light and sight glasses suitably provided.

Agitator Assembly:

1, 2 Nos. Of SS open type Beaters.

1 No. SS Scrapper fitted with PTFE strip on both sides.

1 No. centrally located High Shear Emulsifier optional.

Drive Mechanism For Beater:

Consist of the following

- Suitable HP 1440, 2880 RPM dual sped TEFC motor to work on 415 V, 50 c/s 3 Phase AC supply line, mounted on MS plate.

- Worm reduction gear box coupled to the motor through belt and pulley arrangement.

- Epicyclic gear box coupled to the motor through belt and Epicyclic gear train arrangement to achieve planetary motion.

- Suitable HP 1440 RPM TEFC motor to work on 415V 3 phase 50 c/s AC supply line for High Shear Emulsifier. optional

- The above item are assembled on the top plate which is supported on a Cast iron sliding sleeve with MS gussets.

Main Body: MS column with flange mounted on stool base 2 nos limit switches provided at upper and lower limits of the column to control traverse of the sleeve.

Lifting Arrangement Of The Drive Assembly Mechanical: Consist of

- Suitable HP, 1440 RPM motor working on 415V 50 c/s 3 Phase AC supply line.

- Worm reduction gear box coupled to the motor through belt and pulley arrangement.

- MS STOOL for mounting the reduction gear unit.

- Lead screw and guide bar to guide up and down traverse of the drive assembly.

Lifting Arrangement Hydraulic optional:

- Horse shoe base with suitable gun metal bush housing for 3nos chrome plated guide bars with suitable retaining plate and supports.

- Hydraulic Power pack assembly complete with MS. Tank, suitable HP pump with filter connected to suitable solenoid valve arrangement with control and check valve for preventing dropage of pressurized fluid.

- Power Pack connected with fixed, flexible high pressure inter connecting hose to hydraulic cylinder of suitable lift clamped to the drive head to give smooth up and down traverse.

- Limit switch for controlling up and down traverse motion.

- Control Panel.

- Air break DOL dual speed starter with DOL relay for main motor.

- HRC back up fuses.

- Ammeters for main motor and lift motor.

- Push Button actuator for above operation fitted on control panel.

- The circuit consist of mcbs, relays and contactors is series. Ample overload protection is provided by The MCBs and the relay.

- Wires coming out of the connections are numbered for easy recognition.

Finish All SS parts polished to smooth pharmaceutical finish. All MS part painted to smooth finish.

Options Available Provided:

- Unit with FLP motors and FLP push button station but non FLP panel to be mounted outside FLP area

- Unit in SS 316

- Unit in SS304 cladding for GMP model

- Jacketed bowl for steam, electrical heating

Multipurpose Mixing for Commercial Demands

This planetary mixer is engineered for a variety of applications, including dough kneading, batter blending, and cream mixing. Its variable speed options allow chefs and bakers to achieve precise consistency for different recipes, enhancing productivity in commercial kitchens and bakeries.

Built to Endure Heavy Workloads

Constructed entirely from stainless steel, the mixer boasts a durable framework suitable for demanding industrial environments. The 40-liter capacity accommodates large batches, while its removable bowl simplifies transfer and cleaning, supporting continuous production and hygiene standards.

Safety and Easy Maintenance

Safety is prioritized with an integrated safety switch, and daily upkeep is straightforward thanks to the smooth stainless-steel surfaces and detachable mixing bowl. These thoughtful features ensure the mixer is safe for operators and quick to clean after every use.

FAQs of Planetary Mixer:

Q: How do I operate the 40-liter planetary mixer for best results?

A: To achieve optimal mixing, start by placing your ingredients in the removable bowl, set the desired speed using the manual controls, and activate the mixer. Always ensure the safety switch is engaged before operation for added protection.Q: What types of food products can I use this mixer for?

A: This planetary mixer is suitable for dough kneading, cake batter mixing, cream blending, and other food mixing applications common in industrial and commercial bakeries or kitchens.Q: When should I clean the mixer, and what is the recommended process?

A: It is advisable to clean the mixer after each use. Remove the bowl and attachments, wash them with warm soapy water, and wipe down the stainless steel surfaces. Ensure all components are dry before reassembling.Q: Where can I install this planetary mixer in my facility?

A: Due to its dimensions (900 x 600 x 1200 mm) and weight (150 kg), the mixer should be placed on a stable, flat surface with easy access to a 220 V single-phase electrical outlet. Ensure there is sufficient space for cleaning and bowl removal.Q: What benefits does the variable speed feature offer?

A: Variable speed control allows users to precisely tailor the mixing intensity, ensuring ingredients are mixed thoroughly. This feature ensures consistent quality for a variety of recipes and helps prevent over-mixing or under-mixing.Q: How does the safety switch enhance user protection?

A: The built-in safety switch automatically shuts off the mixer if the bowl or guard is not correctly positioned, preventing accidental operation during maintenance or cleaning.Q: Why is stainless steel material preferred for this industrial mixer?

A: Stainless steel ensures durability, resistance to corrosion, and easy cleaningall crucial for maintaining high hygiene standards and withstanding the demands of industrial and commercial use.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Pharma Manufacturing Equipment Category

Spice Roasters

Price 250000 INR / Unit

Control Mode : Manual

Computerized : No

Type : Other, Spice Roasting Machine

Material : Stainless Steel and Mild Steel

Color : Red

Tablet De Burring and De Dusting Machine

Price 155000 INR / Unit

Control Mode : Automatic

Computerized : Yes

Type : Tablet Deburring and De Dusting Machine, Other

Material : Stainless Steel

Color : Silver

Nauta Mixer-Cone Screw Mixer

Price 250000 INR / Unit

Control Mode : Other, Automatic / SemiAutomatic

Computerized : No

Type : Other, Nauta Mixer (Cone Screw Mixer)

Material : Stainless Steel (SS304 / SS316), Mild Steel (optional)

Color : Silver (Stainless Steel Finish)

Liquid Oral Mfg Plant

Control Mode : Other, PLC Controlled

Computerized : Yes

Type : Automatic Liquid Manufacturing Plant, Other

Material : Stainless Steel (304/316)

Color : Silver

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry