Tray Dryer

Tray Dryer Specification

- Temperature

- Ambient to 200C

- Noise Level

- < 70 dB

- Phase

- Single Phase

- Features

- Uniform drying, double walled insulation, easy to operate, energy efficient

- Frequency

- 50 Hz

- Usage & Applications

- Drying food, pharmaceuticals, chemicals, and other materials

- Type

- Tray Dryer

- Material

- Stainless Steel

- Capacity

- 12 Trays

- Computerized

- No

- Control Mode

- Manual

- Power

- 4.5 kW

- Weight (kg)

- Approx. 200 kg

- Dimension (L*W*H)

- 1220 mm x 910 mm x 1580 mm

- Color

- Silver

Tray Dryer Trade Information

- Minimum Order Quantity

- 01 Unit

- Payment Terms

- Cheque

- Main Export Market(s)

- Australia, North America, Eastern Europe, Middle East, Western Europe, Africa, South America, Asia

- Main Domestic Market

- All India

About Tray Dryer

Owing to our rich knowledge as well as professional workforce, we have achieved a noted position as a leading manufacturer and exporter of Tray Dryer. These dryers are manufactured at our unit, using best quality of stainless steel, procured from trusted vendors. Widely used in chemical and pharmaceutical industries, these dryers are normally supplied with either steam or hot water heating systems. We offer our Tray Dryer at the pocket friendly prices.

Features:

-

Adjustable damper at the outlet

-

Air circulation is done by recirculation blowers

-

Fitted with electronic digital temp controller

Specifications:

- Construction: External 2MM Thkinternal 2MM, THKMOC: cGMP

- Surface Finish: External Buffed to 150 grit matt finish Internal Buffed to 220 grit mirror finish.

- Inlet and Outlet: All dryers have a 5 micron pre filter r at the inlet and a manually infinite adjustable damper at the outlet.

- Door: Doors at provided at the front and, or rear side of the dryer. Door lips are lined with silicon rubber gasket to prevent any leakages. Suitable locking is provided for the doors.

- Air Circulation: Air circulation is done by specially designed recirculation blowers inside the dryer. The blower capacity, static and design depends on the size and model of dryer.

- Heating: Dryers are normally supplied with either steam, electric, thermic fluid, hot water heating system. Suitable heating coils, caloriefiers are provided in the dryers.

- Temperature Control: Temp control system is done by electronic digital temp controller fitted in the control panel. The temp control in the dryer is fully automatic.

- Trays: Trays are available in S.S 304, 316 q. All trays are fully die pressed and with cooved corners. Trays are buffed to mirror finish. Trays are also available in aluminium, Polypropelene, Frp, M.S. galvanized as per clients reqiuirements.

- Trolley: Trolley is provided in the dryers to accommodate trays in it. Trolley truck are used to load and unload the trays into the dryer.

- Control Panel: Automatic control panel is fitted on the side of the dryer. If consists of starters, contactors, safety relays, ckt breakers, indicating lamps, push buttons, timers, controllers etc.

Uniform and Efficient Drying

Our Tray Dryer features advanced double-walled insulation that ensures even temperature distribution across all 12 trays. This design enables uniform drying for food, pharmaceutical, and chemical products, preventing uneven moisture pockets and improving overall product quality. The energy-efficient nature of the dryer reduces operating costs, making it an ideal choice for businesses focused on productivity and cost savings.

Sturdy Stainless Steel Construction

Built entirely from high-grade stainless steel, the Tray Dryer resists corrosion and maintains structural integrity in demanding industrial environments. The durable construction not only extends the equipments lifespan but also ensures the easy cleaning and maintenance necessary for hygienic applications in the pharmaceutical and food processing sectors.

FAQs of Tray Dryer:

Q: How does the manual control mode benefit the operation of the tray dryer?

A: The manual control mode of this tray dryer allows users to easily adjust temperature settings and drying times, giving precise control over the drying process. This flexibility is particularly useful when working with materials that require specific drying conditions or when experimenting with new applications.Q: What types of materials can be dried with this tray dryer?

A: This stainless steel tray dryer is suitable for drying a wide range of products, including foods, pharmaceuticals, chemicals, and various materials that require gentle, uniform heat exposure. Its design ensures compatibility and safe operation for multiple industry needs.Q: When should I use the tray dryer for optimal results?

A: The tray dryer is best used when you need consistent and uniform drying at controlled temperatures, especially for materials sensitive to over-drying or uneven heating. It is ideal for batch processing, product testing, or pilot-scale production runs in various industries.Q: Where can this tray dryer be installed and operated?

A: This tray dryers compact dimensions and single-phase power requirement make it suitable for installation in laboratories, pilot plants, small-scale manufacturing facilities, and specialized industrial production areas. Its stainless steel design allows safe use in environments requiring stringent hygiene.Q: What processes are involved in using the tray dryer?

A: The drying process involves evenly placing materials across the 12 trays, setting the desired temperature (up to 200C), and closely monitoring the process using the manual controls. The effective air circulation and insulation facilitate uniform moisture removal, resulting in reliably dried products.Q: How does this tray dryer enhance productivity and quality?

A: With features like double-walled insulation, uniform drying, and energy efficiency, the tray dryer improves workflow by reducing drying times and ensuring products meet quality standards. It also minimizes operational noise (<70 dB) for a safer, more comfortable workspace.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Pharma Manufacturing Equipment Category

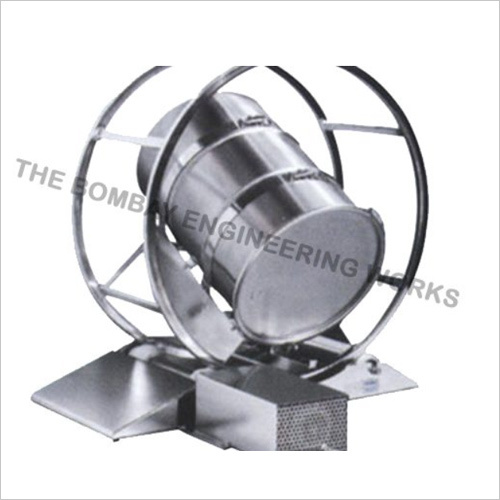

Drum Mixer

Price 150000 INR / Piece

Type : Other, Drum Mixer

Material : Mild Steel

Control Mode : Manual

Computerized : No

Dimension (L*W*H) : 1100 x 800 x 1400 mm

Single Sided Rotary Tableting Machine

Price 150000 INR / Piece

Type : Single Sided Rotary Tableting Machine, Other

Material : Stainless Steel

Control Mode : Automatic

Computerized : Yes

Dimension (L*W*H) : 900mm x 800mm x 1800mm

Coated Semi Automatic Capsule Filling Machine

Price 1050000 INR / Unit

Type : Other, Semi Automatic Capsule Filling Machine

Material : Stainless Steel

Control Mode : Other, Panel Control

Computerized : Other, Semiautomatic

Dimension (L*W*H) : L 1850 mm x W 750 mm x H 1600 mm

Turbo Sifter

Price 650000 INR / Unit

Type : Other, Turbo Sifter

Material : Stainless Steel (SS 304/316)

Control Mode : Other, Manual / SemiAutomatic

Computerized : No

Dimension (L*W*H) : 1200 x 800 x 1600 mm (approx.)

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry